High Performance Twin Cam Heads

|

|

|

|

We've known Dewey Jelen for ten years. He designs and machines his own line of Custom Machined Aluminum Billet Footpegs, Billet Handgrips, "Heel Hammer" Shift Levers and Billet Aluminum "Rammer" Air Cleaner Covers all for Harley-Davidson Motorcycles. But recently he told us about his Porting Service, "The first thing I found out about my 2002 TC88 FXD was that it lacked guts, so I turned it into a 95 Incher," Dewey said. "Result...more torque but not much more power. The hold up was the cylinder heads. Harley made the exhaust port so small that it was choking off. It wasn't the exhaust valve size, but the exhaust port itself that was the culprit." He explained that Harley may be trying to keep things hot for emissions purposes, or whatever, but, "I got out the mill and the hand porting tools to open things up a bit. The results were spectacular! I picked up 20 horsepower by changing cams and a few other things. People asked me to do the same for their bikes and I've come up with two combinations." Street Port: Ports remain essentially the stock size and diameter to keep the torque high. If the customer wants the horsepower increased at higher rpms, he opens up the ports more. Valves are replaced with Manley Race Master SS valves: Inlet 1.840-inch; Exhaust 1.565-inch. Andrews Titanium spring collars are used with stock springs and keepers and H-D valve seals. Heads are milled .030-inch. Combustion chambers are 80cc which gives a 9.8:1 static compression ratio. Dynamic compression ratio is 9.0:1 with an Andrews #26 cam. It includes a Valve job with the valves lapped into place. Included is a Cometic .030-inch head gasket for a better squish band. OEM pistons are good for .510-inch lift. Pro-Street Port:Includes Ferrea (modified) valves: Inlet 1.900-inch; Exhaust 1.565-inch. Andrews Titanium upper spring collars and high lift springs with cams to .590-inch lift. Exhaust port is bored .100-inch oversize. Intake and Exhaust ports are shaped and blended. Guides are shortened and radiused. Valve seats are four angle cut and radiused. Deck is milled .040 to .060-inxh for desired compression ratio. Combustion chambers are belnded and cc'd to match. Comes complete with .030-inch Cometic head gasket. You're dealing with a real person who actually makes his parts himself here in the USA. He's been riding more than 30 years. "In 1974 I took leave from the Army on my '67 Sportster XLCH," Dewey said, "and I recently rode a 120 Merch FXR that I built. It was featured in HOT BIKE magazine." His current ride is a 2002 Dyna FXD 95-inch, " I ported it myself," Dewey said, "It pumps out 108.41 Hp and 109.58 pounds of torque. I'm offering both Pro-Street and Street porting combinations for the TC88 motors as well as my new "Heel Hammer" shift levers for the Dynas and some Softails. Good stuff that works!" Check his air cleaners. Using a Twin Cam 88 Softail on a Dyno Jet 250 Dynamometer HOT ROD BIKES Magazine compared the stock factory air cleaner with a Dewey's Custom Rammer Billet air cleaner with the K&N Screaming Eagle filter element. The results were astounding! Let's get to work on a set of Twin Cam heads, we're burnin' daylight.

First step is to bead blast (silicon beads) the heads and inspect them for wear or damage.

Next step is to disassemble them. Guides are checked for wear. The only parts that will be reused are the bottom spring collars and the keepers.

Notice the intake port hangs over the intake seat. That will be blended later with the milling machine by boring the intake seat to a specific percentage of valve head diameter and boring past the seat about 1/2-inch so to have a perfect transition from seat to port!

At this stage the top surface is lapped on a granite surface plate to make sure it is flat for a tight rocker box seal.

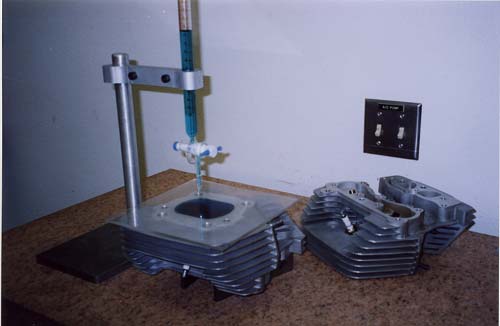

The next step is to CC the heads and make absolutely sure they are the identical size.

Liquid is used to fill the combustion chamber, then measured. Stock H-D is 85 cc but the heads almost always vary from 84-86 ccs and are always off from one to the other about 1 to 1 1/2 ccs.

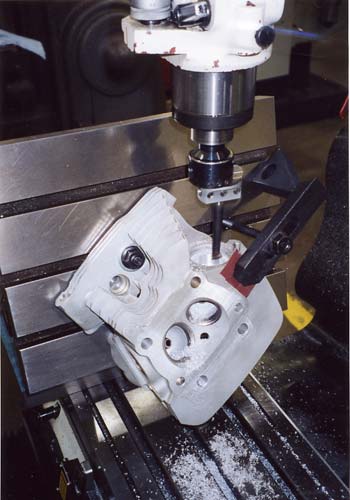

The heads are put on the mill and machined with a fly cutter to take off the desired amount. Depending on the desired compression ratio and the customer's cam. "By machining the head," Dewey said, "you can use a flat top piston and therefore have little or no detonation! I highly recommend WISECO flat top pistons as they have anti-detonation grooves machined in the top of each piston that work !!!" He uses Wiseco piston at 10.7-1 compression. "With this set-up, on 91 octane pump gas," Dewey explained, "there's NO detonation!" He can modify heads from 9.5 to 11.0-1 compression ratio. " I supply the COMETIC .030 head gasket with each set of heads that I port."

The other picture shows the exhaust port being bored out as the stock twin cam heads have a very small exhaust port and that restricts airflow and is also one of the reasons they run so hot.

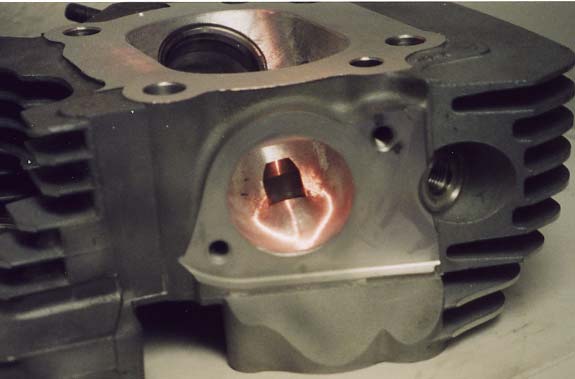

After the boring is complete, Dewey blends the bore cut into the port with a die grinder. Dewey likes to use the stock size exhaust valve to keep the torque high. Dewey is one of the few head porters that doesn't allow a dip in the torque curve with Thunder Header exhausts. Intake guides are also shortened and have new angles cut on them at this time. "There's no reason to change the stock H-D valve guides," Dewey said. "They hold up very well, 100,000 miles." He also doesn't believe in pushing over .570-inch lift cams.

Final stage before assembly: This is the BLACK ART of head porting! Thirty plus years of experience go into this stage.

Here we see Dewey doing his thing. Dewey does this step totally alone, with NO music, just silence and concentration!

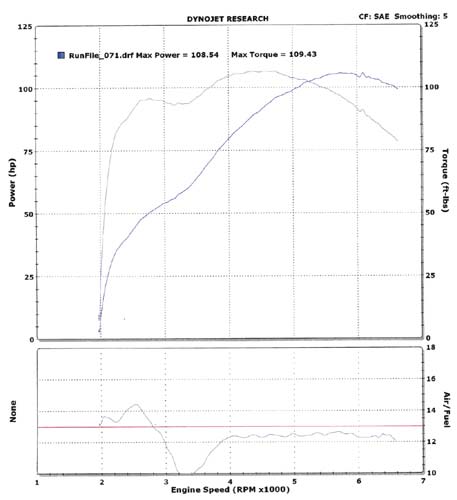

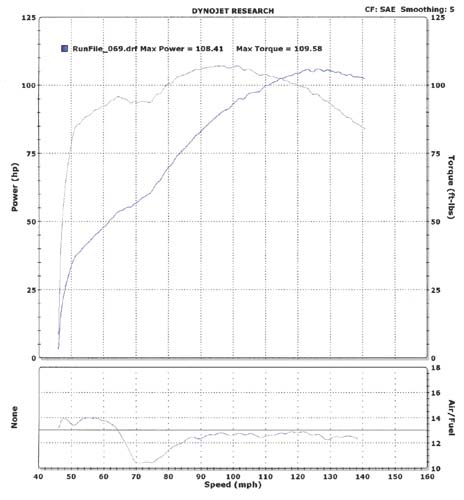

These tests were taken in Farmington, New Mexico, with a 2002 FXD 95-Inch with Dewey's Pro-Street Heads, Andrews 55G Cam, Mikuni 45 Carburetor, 10.5 to 1 compression and Cycle Shack Slip-On Mufflers.

Chart One

Chart Two Black Diamond or Ferrea Intake Valves 1.900 {oversize} also 1.940 and new oversize seats {extra charge}, Manley Street Master SS {modified} Exhaust Valves 1.565. Andrews Titanium upper spring collars and High Lift Springs, cams to .570 lift Exhaust port is bored .100 oversize Intake and Exhaust ports are shaped and blended. Guides are shortened and radiused Valve seats are 4-angle cut and radiused Deck is milled .060 for 10.5--1 compression ratio with flat top piston {Wiseco}, Combustion chamber is blended an CC'd Includes Cometic .030 Head Gaskets 3108 Pontiac Dr. Farmington, NM 87401 (505) 326-5998 WWW.DEWEYSPEGS.COM Back to The Garage on Bikernet... |